In screening and separation, small inefficiencies can lead to big problems. Lost production time, inconsistent product quality, premature screen failure, and constant changeouts are often accepted as “part of the process.” In reality, many of these issues trace back to one root cause: screens that weren’t designed for the product or the process.

Off-the-shelf screening solutions may look convenient, but they often cost more over time.

Every Material Behaves Differently

Particle size, density, moisture content, shape, and abrasiveness all affect how material moves across a screen. A mesh that works well in one application can blind, peg, or wear prematurely in another. When screens aren’t matched to the material, performance suffers—and so does throughput.

That’s why effective screening starts with understanding the product itself.

Your Process Matters Just as Much

Beyond the material, operating conditions play a critical role. Vibration speed, feed rate, screen tension, and equipment configuration all influence screen performance. Ignoring these variables leads to trial-and-error fixes that waste time and money.

Screens should be designed to support the process—not fight against it.

Custom Screens Deliver Measurable Results

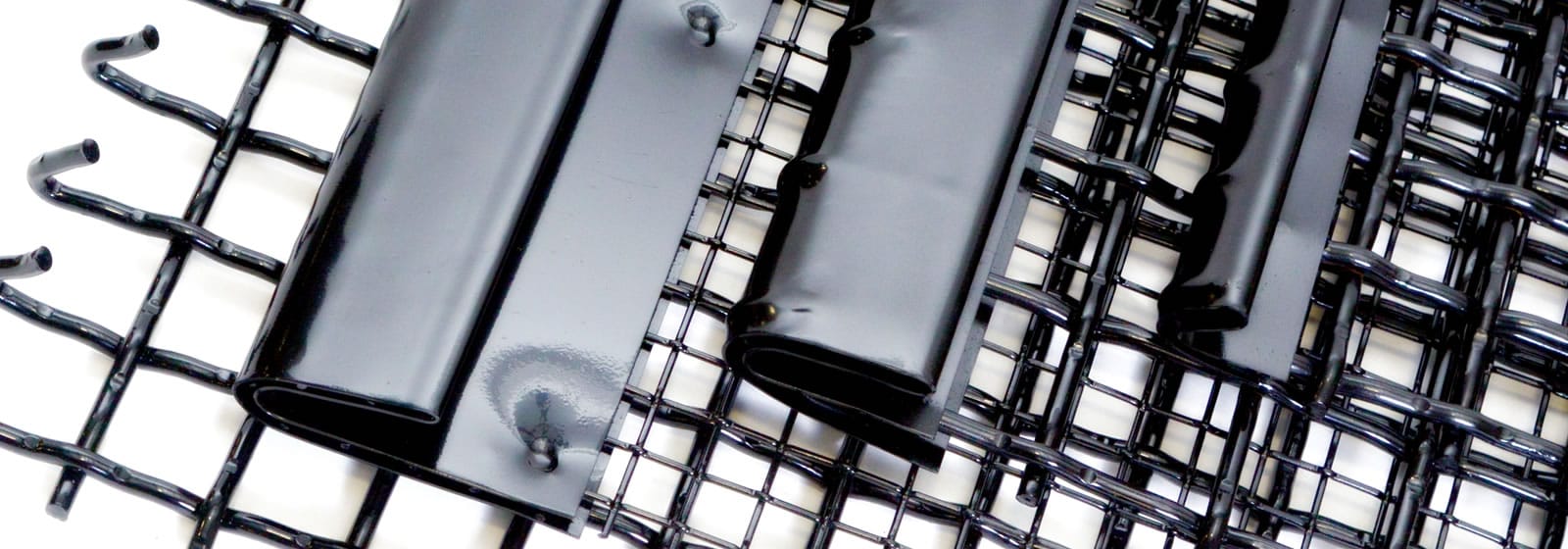

At Compass Wire Cloth, we build screens specifically for the customer’s product and process. By tailoring mesh style, wire diameter, and construction method, we help customers:

- Improve separation efficiency

- Reduce blinding and pegging

- Extend screen life

- Maintain consistent product quality

The result is less downtime and more predictable performance.

Engineering Support Makes the Difference

Custom screens are only as good as the engineering behind them. Compass Wire Cloth’s engineering team works directly with customers to evaluate applications, troubleshoot existing issues, and recommend solutions that make sense operationally—not just on paper.

This collaborative approach eliminates guesswork and ensures screens perform as intended from day one.

Speed and Reliability When It Matters Most

Even the best screens eventually need replacement. When that happens, downtime can’t wait. Compass Wire Cloth supports customers with:

- Quick turnaround times

- Expedited order fulfillment and 24-hour service

- In-house stocking of common materials

This readiness allows us to respond fast—helping customers keep operations moving.

A Better Way to Screen

Screening doesn’t have to be a constant problem to manage. With the right partner, it becomes a process you can rely on.

Compass Wire Cloth combines personalized service, engineered solutions, and fast response times to deliver screens built for real-world performance—because one-size-fits-all rarely fits anyone well.

Ready to talk about a screen built for your process? Our team is here to help.